Chocolate pumps

Gear pumps or Rotary lobe pumps

Steimel chocolate pumps are used in machinery and equipment for the processing and production of chocolate. Installation in stationary and mobile tank systems or storage and melting containers for chocolate is possible. By using the rotary lobe pump, gentle material handling of prodcuts containing fruit or grain can be achieved. Steimel pumps are installed in production lines as process pumps for the production of cosmetic creams, oils and lotions.

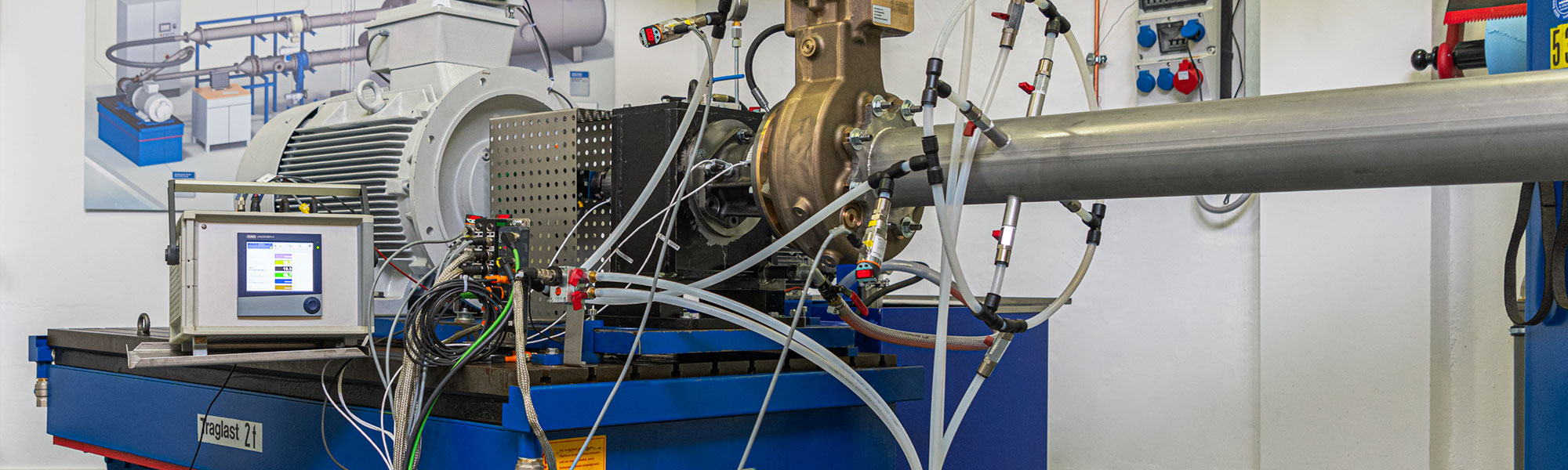

Fig.: Rotary lobe pump type SKK/HKK

Typical media in the application of chocolate & food:

- Bread dough

- Chocolate coating

- Chocolate mixture

- Cocoa butter

- Cocoa mass

- Cooked sugar

- Cooking oil

- Fats

- Fat glazes

- Flavours

- Fruit mash

- Gelatine

- Glucose

- Hazelnut paste

- Honey

- Toffee paste

- Liquorice mass

- Mashing

- Molasses

- Mustard

- Nougat

- Palm oil

- Pastes

- Peanut paste

- Peanut butter

- Rapeseed oil

- Raw cocoa

- Soya oil

- Sour dough

- Sugar solution

- Syrup

- Waffle dough

and more...

If your media is not listed here in the application of chocolate / food, please contact us - we will help you.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Designs and key data of the chocolate pumps:

- Gear pump or rotary lobe pump

Operating parameters depending on model and application: - Flow rate: max. 3.400 cm³ / rev

- Maximum pressure: max. 20 bar

- Operating temperature: max. 200 °C

- Viscosity range: max. 100.000 mm² / s

- Heatable

- Optional with pressure relief valve

- CIP / SIP capability possible depending on model

- Material design:

- Rotors: Case hardening steel or stainless steel

- Housing parts: Grey cast iron or stainless steel

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

Pump applications:

Seawater Cooling water Paints & Varnishes Bitumen Chocolate / Food Lubricating oil / Greases Other media / applications= suitable pump types for the selected application.