ZPAL Palletizer / Depalletizer

Parts supply

Parts supply

The supply of the parts into the palletizer can be done by typical transport systems such as conveyor belts. It can take place at several positions. The robot picks up the parts individually or in packs and sorts them into/onto the provided carrier plates in predefined set patterns.

Faulty parts identification option

In the material receiving area, faulty parts can be identified via optional systems for parts measurement, a weighing device or optical parts recognition systems. Separate sorting and discharge of these parts ensures reliable palletizing of the good parts and serves for QA-compliant parts transfer to subsequent processing stations. As an option, real-time reporting of the deviation to the upstream production process is possible.

Batch report

Batch data (history record) are recorded and can be transferred to production control systems.

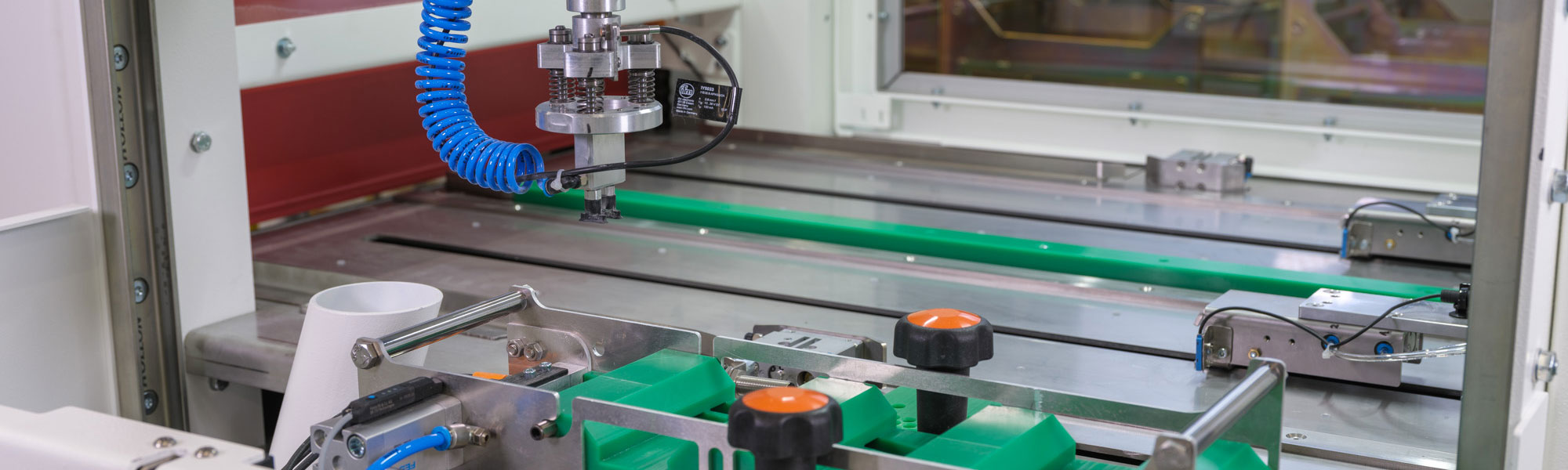

Material supplied via a conveyor belt into the parts transfer of the ZPAL palletizer

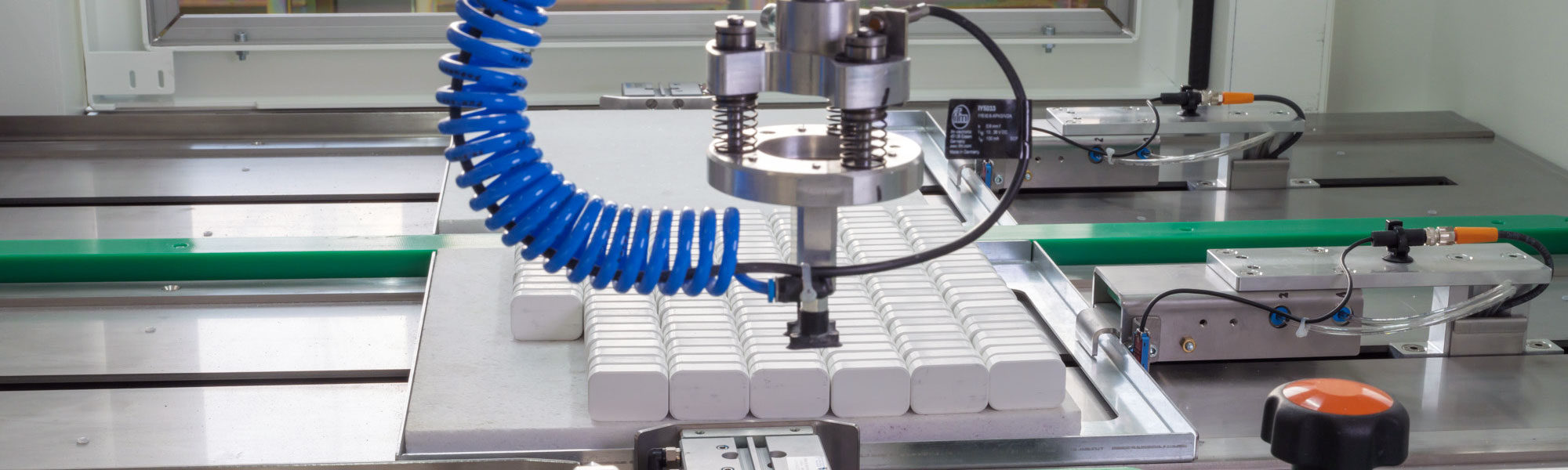

Parts weighing and sorting out the faulty parts

Options in the material supply

Possible here are pre-treatment process steps in the infeed (e.g. deburring of the parts), sorting stations (e.g. a sorting switch) as well as part-specific solutions for separating and pre-positioning the parts.

More topics about the ZPAL palletizer: